Location of Heavy Metal Contamination: Former Auto Assembly Plant St. Louis, MO

Project Info: 10,000 tons of lead contaminated soil in excess of 100 mg/l TCLP

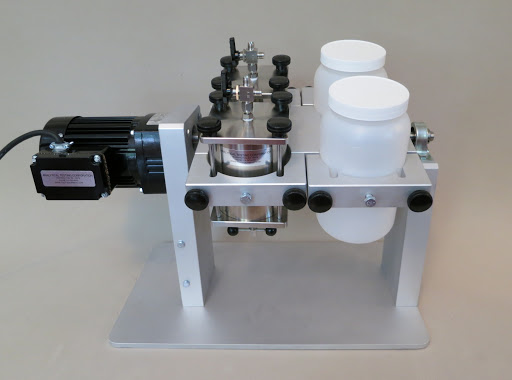

Product used to stabilize heavy metal contamination:

BLASTOX® used at 4% dose rate to stabilize heavy metal contamination. After use of Blastox®,the contractor was able to dispose of the soil in a non-hazardous landfill saving them lots of money.

Lead solder, e-coat, and related lead bearing manufacturing debris were buried in several areas and caused heavy metal contamination in excess of 100 mg/l TCLP.

The general contractor that dismantled the plant and removed subsurface structures, was also contracted to remediate

contaminated soil.

Prior to modern waste disposal regulations, the assembly plant dug trenches on the plant property and used them to burn debris and bury waste. Blastox® is in the photo above in the white bulk bags. The product is spread over the contaminated area then mixed in well with the soil causing a chemical reaction where Blastox® will bond with the lead and encapsulating it to render it non-hazardous and non-leachable.

Because of its effectiveness for heavy metal contamination, Blastox had been used successfully on thousands of tons of heavy metal contaminated soil. ts chemistry has a proven long-term stability benefit. You can apply it at low dose rates and have peace of mind knowing that the soil remediation waste will remain stable, always.

If the contaminated soil exceeds the Toxicity Characteristic Leaching Procedure (TCLP) limits, stakeholders should be aware that remedial applications, such as Blastox exists that can be added directly to the soil to render it non-hazardous. This significantly drives down the cost of disposal as hazardous waste transportation and hazardous waste disposal are avoided, allowing for local, non-hazardous waste disposal.