What is Method 1311?

When it comes to determining if a waste is hazardous from a disposal standpoint, there is only one test method that matters. USEPA mandates the use of Method 1311, Toxicity Characteristic Leaching Procedure (TCLP) for determining if a waste is hazardous or non-hazardous for disposal purposes.

When considering options for waste treatment, the first target is to produce a waste that is not hazardous according to EPA RCRA regulatory limits. If baghouse dusts, foundry sands or spent blasting media, for instance, are characteristic hazardous wastes, they cannot be safely disposed until the characteristics are treated (or stabilized in-process through the addition of reagents) below federal and state regulatory standards using method 1311.

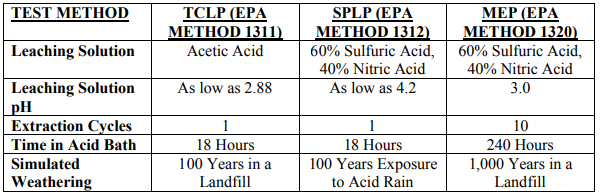

The TCLP test was designed to test for these characteristics by simulating leaching in an acidic landfill environment. The EPA has designed other testing methods, including the SPLP (Synthetic Precipitation Leaching Procedure) and MEP (Multiple Extraction Procedure) tests. These three tests have some important differences.

According to the EPA Solid Waste Manual 846, the SPLP test (Method 1311) “is designed to determine the mobility of both organic and inorganic analytes present in liquids, soils and wastes.” In that same EPA Manual, MEP Method 1320 “is designed to simulate the leaching that a waste will undergo from repetitive exposure to acidic leachate.” This method uses a TCLP followed by 9 extractions of the simulated acid rain on the same sample. Generally speaking, the MEP is a more stringent test for the following reasons:

- SPLP tumbles the sample in a single extraction for 18 +/- 2 hours (similar to TCLP)

- MEP tumbles the sample in an initial TCLP extraction, followed by 9 additional full extractions (24 hours per each extraction)

- MEP extraction fluid is a sulfuric/nitric mix that is 20 to 100 times more acidic than SPLP

Testing Chart

The 10 total MEP extractions include 240 hours of tumbling. Because of this, the acid leach of MEP is 13 times longer than SPLP (18 hours of tumbling). The TCLP and SPLP were designed to simulate 100 years exposure in a landfill. The MEP was designed to simulate 1000 years in a landfill. For long-term performance testing, the EPA has developed the MEP to address this need, not the SPLP.

Method 1311 is the current protocol required by EPA to characterize a waste for disposal.

Video on Proper Sampling Methods Of A Waste Pile

This shows you various methods how to take a proper sample of a waste pile used for testing.