What is Firing Range Remediation?

Lead contamination is a major environmental concern at firing ranges due to the high volume of lead bullets and shot that accumulate in soil and backstops. Proper firing range remediation is essential to prevent lead migration, ensure regulatory compliance, and maintain a safe environment. Blastox® 215 is a proven solution for stabilizing lead in contaminated soil, making it non-hazardous and environmentally compliant.

This discussion includes some key characteristics affecting potential firing range remediation as well as recommended best practices.

- Firing Range Remediation Design Parameters for Effective Lead Management

- Managing Lead Environmental Impact at Operating Ranges

- Site Specific Considerations for Operating and Closed Facilities

- Recommended Best Practices for Range Remediation

Blastox® 215: Lead Management for Shooting Range Remediation Projects

If the contaminated area exceeds the Toxicity Characteristic Leaching Procedure (TCLP) limits, stakeholders should be aware that firing range remediation applications such as Blastox exists that can be added directly to the site to render it non-hazardous. This significantly drives down the cost of disposal and hazardous waste disposal is avoided, allowing for, non-hazardous waste disposal.

Benefits of Using Blastox® 215 for Firing Range Remediation

Lead contamination is a major environmental concern at firing ranges due to the high volume of lead bullets and shot that accumulate in soil and backstops. Proper remediation is essential to prevent lead migration, ensure regulatory compliance, and maintain a safe environment. Blastox® 215 is a proven solution for stabilizing lead in contaminated soil, making it non-hazardous and environmentally compliant.

Permanent Lead Immobilization – Converts lead contamination into a stable, non-leachable form to prevent contamination.

Regulatory Compliance – Helps meet federal, state, and local environmental standards for hazardous waste.

Easy Application – Can be mixed directly with contaminated soil using standard equipment.

Cost-Effective – Reduces disposal costs by allowing treated soil to be classified as non-hazardous.

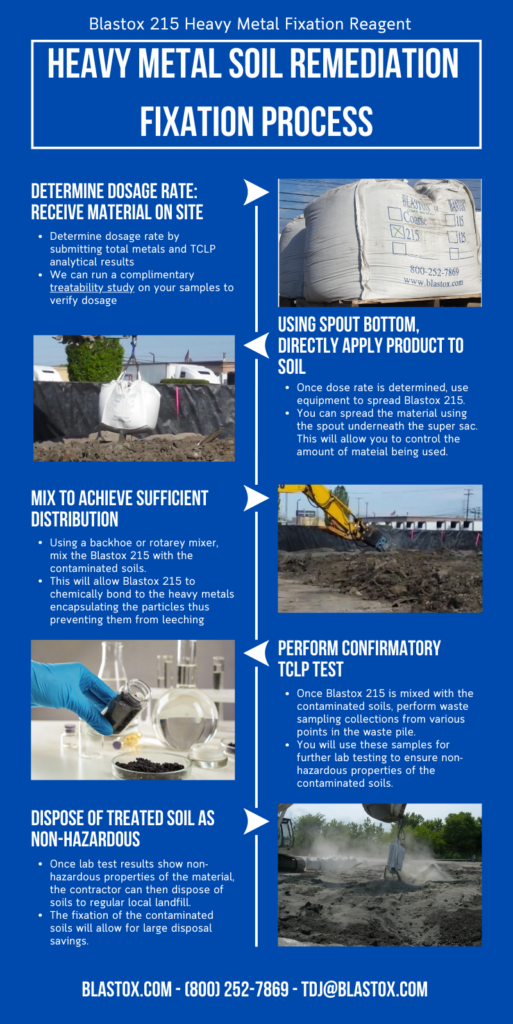

Application Process

Site Restoration – Once stabilized, the treated soil can be safely managed, reused, or disposed of as non-hazardous material.

Site Assessment – Analyze soil contamination levels to determine the appropriate Blastox® 215 dosage.

Mixing & Treatment – Incorporate Blastox® 215 into the impacted soil using mechanical mixing or blending methods.

Testing & Verification – Conduct TCLP testing to confirm compliance with hazardous waste regulations.

Testing & Verification – Conduct TCLP testing to confirm compliance with hazardous waste regulations.

Proven Performance

Blastox® 215 has been used successfully at numerous firing ranges across the U.S., providing a reliable and efficient method for lead stabilization. Whether for active range maintenance or full-scale site remediation, it offers a simple and effective way to manage lead contamination.

In addition to managing firing range remediation projects, it’s being used successfully on thousands of tons of contaminated soil. Its chemistry has a proven long-term stability benefit. You can apply it at low dose rates and have peace of mind knowing that the waste will remain stable, always.

About Us

For more than 30 years, TDJ Group has assisted the metal casting industry (ferrous & non-ferrous), lead paint sandblasting, and soil remediation industries in the stabilization of heavy metal contaminated wastes. More than 1,000,000 tons of industrial wastes have been eliminated or safely stabilized using TDJ chemistries, and more than 150,000,000 square feet of lead paint have been removed using TDJ chemical abrasive additives. Together, this helps minimize the impact of lead hazards across many industries. Companies that perform environmental remediation services are realizing the cost savings and long term stability features that our chemistries afford. TDJ chemistries are the industry model for safe, cost-effective solutions for heavy metal waste treatment and firing range remediation projects.