Can lead paint waste go to a regular landfill?

Removing lead-based paint is a necessary step in maintaining older bridges, industrial facilities, tanks, and steel structures. But once the paint is removed, that critical question quickly follows.

For many contractors, project owners, and municipalities, the answer can mean the difference between a manageable project and one overwhelmed by high disposal costs, regulatory paperwork, and long-term liability. Understanding how lead paint waste is classified—and how it can be managed safely—is essential before blasting ever begins.

What Is Lead Paint Waste?

Lead paint waste is the debris created when lead-based coatings are removed from a surface. This waste typically includes:

- Spent abrasive blasting media

- Paint chips and dust

- Surface debris containing lead

Because lead is a toxic heavy metal, this waste is closely regulated. If it is classified as hazardous, it must be transported and disposed of at a hazardous waste landfill, which dramatically increases project costs and complexity.

Why Lead Paint Waste Is Often Considered Hazardous

The U.S. Environmental Protection Agency (EPA) determines whether lead paint waste is hazardous using a test called the Toxicity Characteristic Leaching Procedure (TCLP). In simple terms, this test measures how much lead can leach out of the waste if it were exposed to landfill conditions.

- If the TCLP result is 5.0 mg/L or higher, the waste is considered hazardous

- If it is below 5.0 mg/L, the waste may be disposed of as non-hazardous

Untreated lead paint waste often exceeds this limit, especially when abrasive blasting is used. That means many projects automatically assume hazardous disposal is unavoidable.

Can Lead Paint Waste Go to a Regular Landfill?

Yes—but only if the lead paint waste is properly treated so it passes TCLP testing.

Regular (non-hazardous) landfills are allowed to accept lead paint only when testing confirms that lead will not leach at hazardous levels. Without treatment, most lead paint fails this requirement.

This is where many projects run into trouble. Contractors may remove paint successfully, only to discover afterward that the waste cannot be disposed of affordably. At that point, options are limited and costs escalate quickly.

The Hidden Costs of Hazardous Lead Paint Waste

When lead paint is classified as hazardous, projects face:

- Much higher disposal fees

- Longer haul distances to hazardous waste landfills

- Increased transportation costs

- Generator status and additional EPA reporting

- Long-term liability for hazardous waste disposal

In some cases, disposal costs can exceed the cost of the actual blasting work.

How Blastox® Changes the Equation

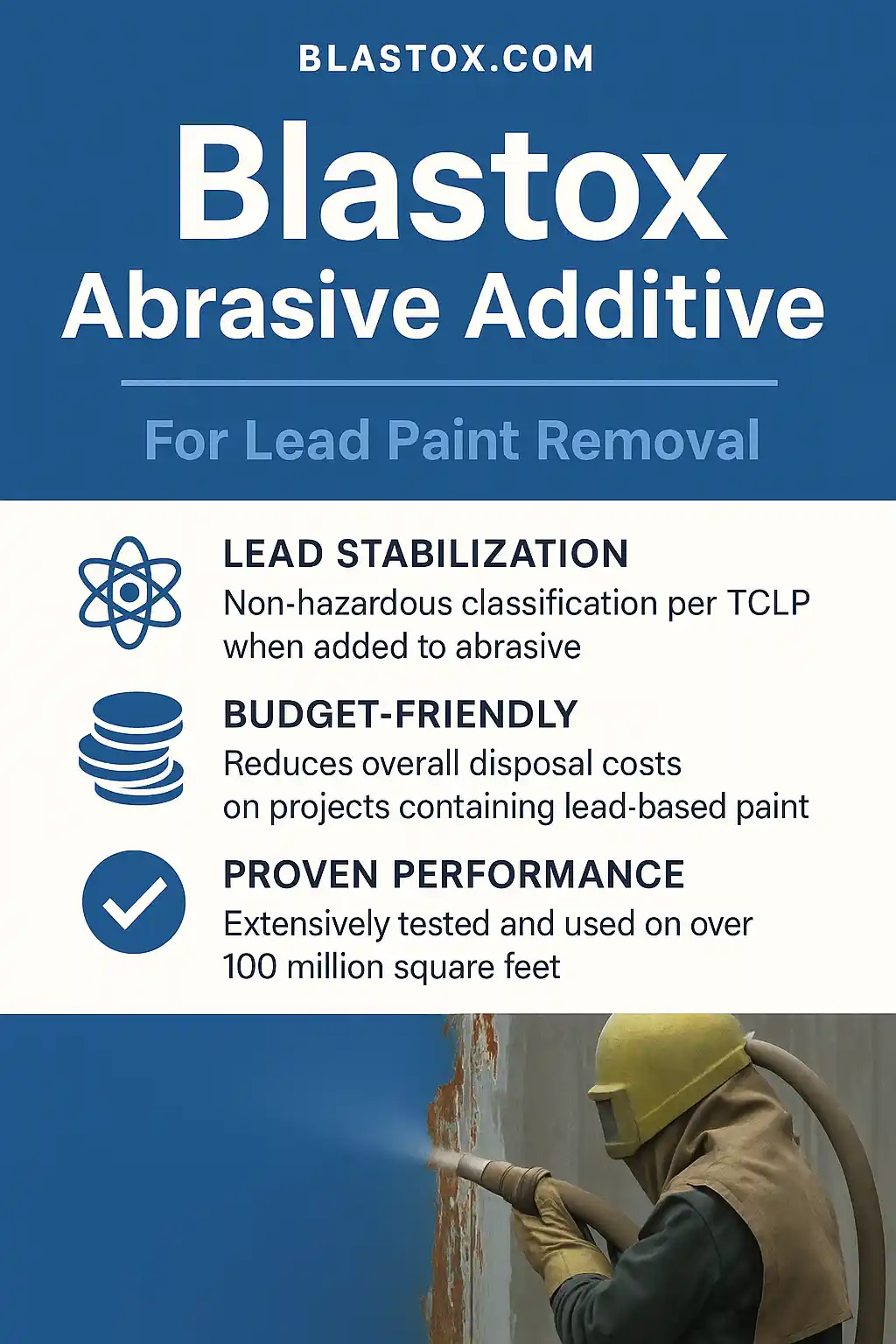

Blastox® is a one-step lead paint abatement additive designed to address the problem at its source. Instead of trying to treat lead paint waste after it is generated, Blastox® stabilizes lead at the moment the paint is removed.

When Blastox® is pre-blended with abrasive media and used during blasting:

- Lead is chemically stabilized as the paint is removed

- The waste is rendered non-hazardous under TCLP testing

- The resulting lead paint can typically be disposed of in a regular landfill

This proactive approach eliminates the uncertainty that often comes after blasting is complete.

Benefits of Using Blastox® for Lead Paint Waste

1. Non-Hazardous Disposal

When used correctly, Blastox® allows lead paint waste to pass TCLP testing, making disposal in a regular landfill possible.

2. Significant Cost Savings

Non-hazardous landfills are far more common and far less expensive than hazardous facilities. This reduces both disposal and transportation costs.

3. One-Step Application

Blastox® is used as part of the blasting process. There is no secondary treatment step, no additional labor, and no specialized equipment required.

4. Reduced Regulatory Burden

By avoiding the generation of hazardous waste, many projects can avoid hazardous waste generator status, reducing paperwork and liability.

5. Proven, Accepted Technology

Blastox® has been tested and accepted by federal and state agencies and has been used successfully on hundreds of millions of square feet of lead paint removal projects.

Planning Ahead Is the Key

One of the most common mistakes in lead paint removal projects is waiting until after blasting to think about disposal. At that point, options are limited and costs are locked in.

By planning ahead and using Blastox®, contractors and owners can:

- Know their disposal path before work begins

- Control costs from the start

- Reduce environmental and regulatory risk

Final Thoughts

So, can lead paint waste go to a regular landfill?

The answer is yes—if it is properly stabilized and tested.

Blastox® provides a proven, practical way to stabilize lead paint during removal, allowing projects to avoid hazardous waste classification, reduce costs, and simplify compliance. For anyone responsible for lead paint abatement, understanding and planning for waste management is just as important as removing the paint itself.