Contaminated Soil Mixing Method

The keys to a successful contaminated soil mixing method is (1) using the right reagent, (2) using the right dosage and (3) achieving good mixing of the reagent and the waste. If there has been extensive testing of the remedial site that shows both the lateral limits and depth of the contamination, then it is recommended that a grid be established over the area before mixing begins.

Typically, a grid of 25’ x 25’ or 50’ x 50’ is used when contamination is deeper than a foot. Larger grids may be more efficient if contamination is shallow. The grid allows the application of the reagent at varies dosages, from grid to grid, and it is an effective way to help allocate premeasured amounts of the reagent. Blastox 215 is a versatile heavy metals stabilization reagent that is effective across a wide variety of waste types, metal concentrations and application methods.

As an example, using a 25’ x 25’ grid where the contaminated soil mixing method extends down 3’ and soil with a density with a ratio of 1.4, the calculation of the weight of the soil and the Blastox dosage at 3% by weight would be: 25’ x 25’ x 3’= 1875 cu.ft, or 69.45 cu yds x 1.4 = ~ 97 tons. 97 tons x 3% dose = 3 tons of reagent. The dose is 3% after mixing. So the formula to determine the tons of Blastox needed would be 97 tons / (1- 0.03) = 100 tons. After mixing, there will be 100 tons.

To apply Blastox 215 using a grid system, the predetermined amount for each grid is spread evenly across the surface. This can be done with a lime spreader or regular construction equipment, such as a skid loader or backhoe. If the contamination is in the top 6” to 10”, a disc or tiller can be used. For deeper areas, most contractors use a backhoe to mix in the reagent. The soil should be turned over, or mixed, with a backhoe or loader at least 5 or 6 times to achieve a proper contaminated soil mixing method. Water may need to be added if the soil or waste is dry.

If the contamination is deeper, it is recommended that the mixing be done in lifts, with each lift about 3 ft- 4 ft deep. Once one lift is mixed, a composite sample of the waste can be collected for testing. The sampling can occur immediately after mixing. When the test results show that the stabilization has achieved the project’s performance goal, the waste can be removed and stockpiled or loaded out directly, depending on the requirements of the work plan.

Dosage Determination

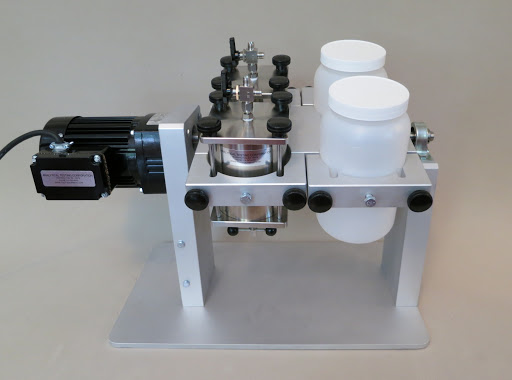

Determining the right Blastox dosage for the contaminated soil mixing method can been done a couple of ways. For simple projects that have fairly homogeneous waste that involve lead contamination where the TCLP values are in the lower range (~ 50 ppm or less), the treatment dosage is likely to fall in a narrow range. Typically, the Blastox 215 dosage averages 2% – 5% by weight. The higher hotspot areas get the higher dosage, the lower TCLP areas get a lower dose. Advance treatability testing is typically not necessary. However if the waste matrix is complex with various types of debris or sludges, it is preferable to do advance testing.

If advance testing is conducted, a waste sample from the highest TCLP data point is always the best starting point for the treatability test. Also, if there is a large quantity of soil or waste involved (5,000 tons +), it can be helpful to pick another sample from a data point that represents the largest volume of soil. When multiple samples undergo treatability testing, it’s common to end up with different recommended dosages for each distinct area. It also helps establish a range of possible reagent dosages, even for areas not tested.

Because of its effectiveness, Blastox has been used successfully on thousands of tons of heavy metal contaminated soil mixing method projects. Its chemistry has a proven long-term stability benefit. You can apply it at low dose rates and have peace of mind knowing that the soil remediation waste will remain stable, always. Its smaller particle size provides more reactive surface which is beneficial when stabilizing heavy metals for contaminated soil remediation projects. Due to the low dose rate and competitive pricing, Blastox® 215 is becoming an effective resource for many engineers and also project managers.

Download our product technical data sheet for more information. Also the video above gives a summary of a past soil remediation project were Blastox 215 treated a large area of lead contamination. This saved the contractor over $1.4 Million in disposal costs, saving the project and allowing them to continue working.